News & Downloads

SERVUS Blog

Warehouse Automation Trends

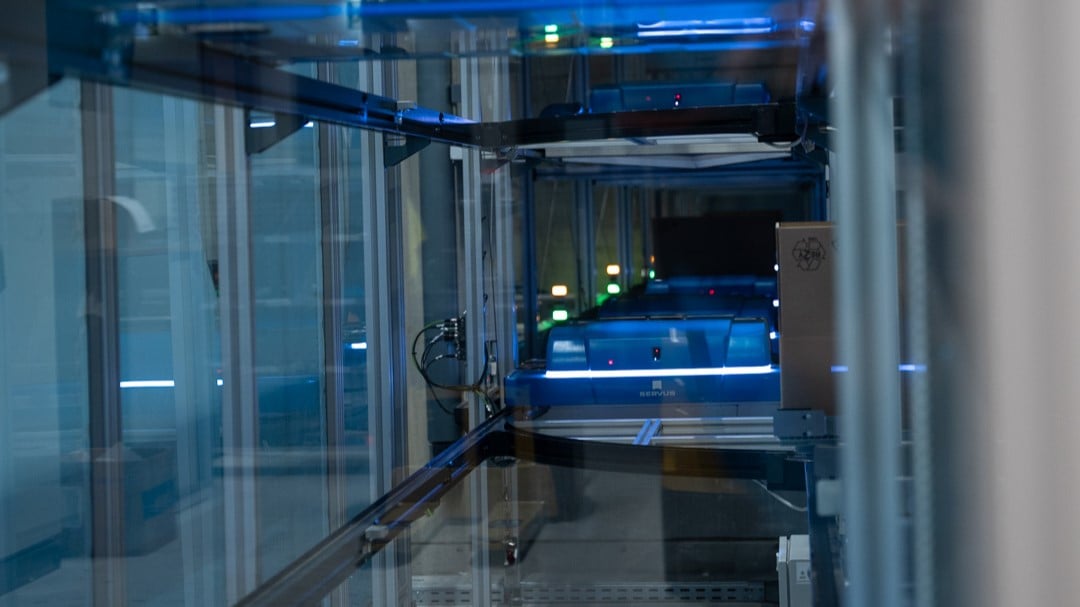

How Hirschmann Automotive in Rankweil is revolutionizing its intralogistics concept

In our latest blog, we take a look behind the scenes at our customer, Hirschmann Automotive and its latest project: the implementation of the Servus ARC5 system at its headquarters in Rankweil. Below are answers to these questions: Why Hirschmann choose now to invest in modern intralogistics? Which warehouse automation trends will accompany us this year? What does an efficient and future-proof intralogistics solution look like?

From the demand for sustainable management and production, to technological developments and innovations, to rising cost pressures, modern intralogistics today faces many diverse challenges. A future-proof intralogistics system is the solution that seeks to address all these issues. For Servus Intralogistics with the following featuers:

Who says that automatic goods flows, short throughput times and process realiable goods transports are not also needed in hospitals? Servus puts hospital intralogistics in a new light.

How a smart buffer optimizes your production logistics

Different cycle times, varying delivery quantities, last-minute orders, one-piece-flow production (small batch sizes) or even product idle times are the daily challenges for optimally flowing production logistics.

A masterpiece of networked thinking is needed to turn complicated problems into simple solutions. The workshop is clearly the right tool for this. In this blog post you can find out how a workshop with Servus Intralogistics works and what lies behind our neutral consulting concept.