News & Downloads

SERVUS Blog

Warehouse Automation Trends

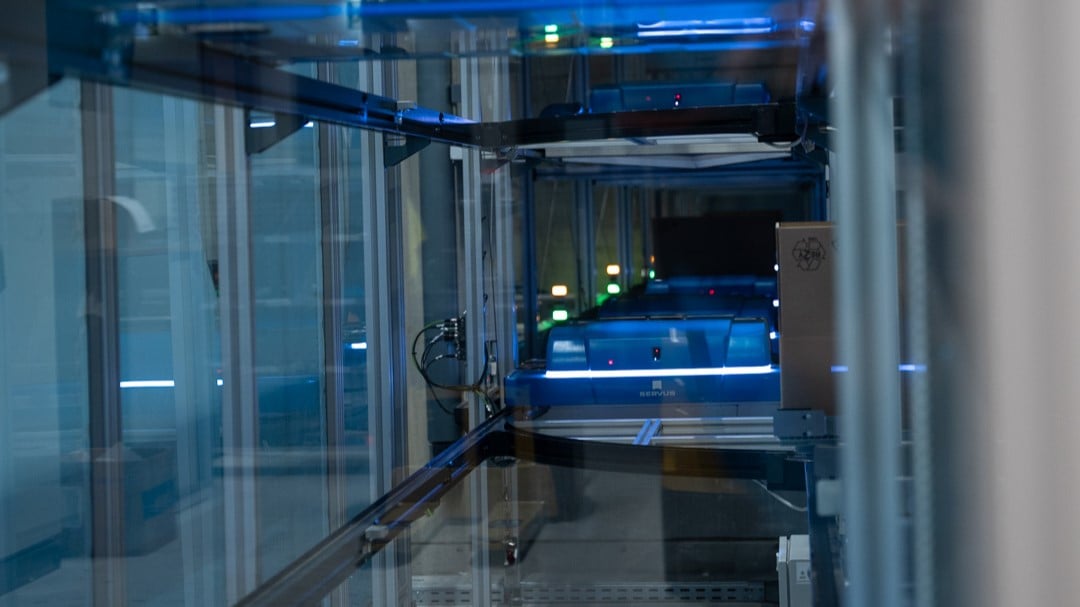

How Hirschmann Automotive in Rankweil is revolutionizing its intralogistics concept

In our latest blog, we take a look behind the scenes at our customer, Hirschmann Automotive and its latest project: the implementation of the Servus ARC5 system at its headquarters in Rankweil. Below are answers to these questions: Why Hirschmann choose now to invest in modern intralogistics? Which warehouse automation trends will accompany us this year? What does an efficient and future-proof intralogistics solution look like?

From the demand for sustainable management and production, to technological developments and innovations, to rising cost pressures, modern intralogistics today faces many diverse challenges. A future-proof intralogistics system is the solution that seeks to address all these issues. For Servus Intralogistics with the following featuers:

Who says that automatic goods flows, short throughput times and process realiable goods transports are not also needed in hospitals? Servus puts hospital intralogistics in a new light.

How a smart buffer optimizes your production logistics

Different cycle times, varying delivery quantities, last-minute orders, one-piece-flow production (small batch sizes) or even product idle times are the daily challenges for optimally flowing production logistics.

A masterpiece of networked thinking is needed to turn complicated problems into simple solutions. The workshop is clearly the right tool for this. In this blog post you can find out how a workshop with Servus Intralogistics works and what lies behind our neutral consulting concept.

A workshop with Servus Intralogistigs:

There were times when the two areas of warehouse and production were strictly separated like two kingdoms. Both worked side by side. Instead of the pull principle, the push principle was practised, warehouses were seen as isolated solutions. Although this is still often the case, it is no longer keeping with the times. Nowadays, an automated storage and retrieval system (ASRS) should be fully integrated into the flow processes and serve as a production buffer. The ASRS should supply production areas directly and at the right time with the right material. This brings several advantages - and thus future security. As a result, the company remains competitive in the age of Industry 4.0:

Lean Management: for the production AND intralogistics of the future

Better, faster AND more cost-efficient sounds impossible? – It’s not! The solution: Lean Management in combination with just-in-time. While in the past the strategic decision was either in the direction of speed with a loss of quality, or accuracy and high quality with the aftertaste of slow processes, nowadays the entire process is taking on new forms. Lean consolidates the overall strategy of successful companies and we at Servus Intralogistics in Dornbirn support you on this path. With the Servus System, we facilitate your development into a Smart Factory.

Efficient picking to save essential seconds

by Juan Martin

Servus promised to serve its customers and eliminate waste when it started to develop the Servus System. Nothing has changed about this. This is why Servus now enables its customers to perform “hands-free” picking.

The "invisible" warehouse

The autonomous robotic carriers from Servus Intralogistics are able to use the tracks on which they run for storage at the same time. This way, customers can have an “invisible” warehouse. Swiss wholesaler Hasler in Winterthur saved precious floor space that could be used much more sensibly.

Increasing efficiency in the warehouse by smart strategies in the ASRS

Smart management of the automated storage and retrieval system (ASRS) starts with initial filling. Goods in the ASRS are mostly stored chaotically. Even for chaotic storage, the WMS (Warehouse Management System) will make sure that one and the same article is stored evenly distributed across all aisles of an ASRS during placement in storage.

.jpeg)