News & Downloads

SERVUS Blog

Efficient picking to save essential seconds

by Juan Martin

Servus promised to serve its customers and eliminate waste when it started to develop the Servus System. Nothing has changed about this. This is why Servus now enables its customers to perform “hands-free” picking.

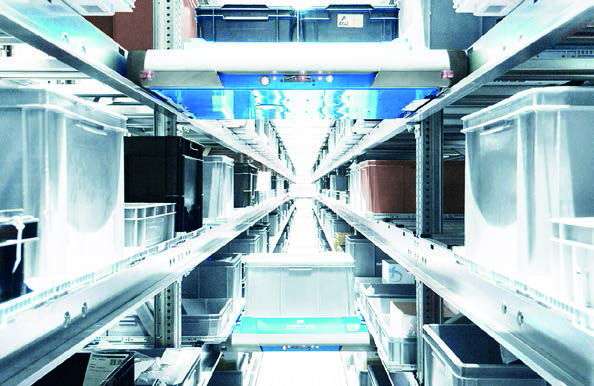

The "invisible" warehouse

The autonomous robotic carriers from Servus Intralogistics are able to use the tracks on which they run for storage at the same time. This way, customers can have an “invisible” warehouse. Swiss wholesaler Hasler in Winterthur saved precious floor space that could be used much more sensibly.

Increasing efficiency in the warehouse by smart strategies in the ASRS

Smart management of the automated storage and retrieval system (ASRS) starts with initial filling. Goods in the ASRS are mostly stored chaotically. Even for chaotic storage, the WMS (Warehouse Management System) will make sure that one and the same article is stored evenly distributed across all aisles of an ASRS during placement in storage.

How Erwin Halder Improves Material Flows and Drastically Shortened Throughput Times

A new logistics system essentially improved Erwin Halder KG's material flows and drastically shortened throughput times. Halder remains highly flexible for the future with its new system, built around autonomous robotic carriers.

The ASRS of the Future

Changing consumer behaviour makes products smaller and smaller, more customised and specific for individual customers. Batch sizes in production reduce and product variations increase as a consequence. In order to meet these requirements, production and processes need to adjust and become more efficient. In the best case, production would be just-in-time. This can only work if the warehouse and production are optimally coordinated with each other. The automated storage and retrieval system must be fully integrated into the material flow. This way, the necessary materials can be supplied to production just-in-time after the order is received, inventories in stock can be reduced and available areas can be used for value-added operations.

Integrating Warehouses into the Process Flows to Be Ready for the Future

Once, there was a time when warehouse and production areas were as strictly separated as two kingdoms. They worked side by side. Push was practised instead of pull. Warehouses were considered island solutions. Though this is still often the case today, it is no longer the state of the art. Today, an automated storage and retrieval system (ASRS) should be fully integrated into the process flows. It should be a buffer for production. An ASRS is to supply production directly and with the right material at the right time. This has many benefits for the customers:

Software in Intralogistics, What you Should Pay Attention to

A storage management system describes in essence a system for the management of storage locations and stock. A Warehouse Management System or WMS generally means instead the control and optimisation of complex flows of goods of intralogistics. In addition to the elementary functions such as storage area and quantity management as well as the control of the flow of goods, it also includes extensive methods for controlling the system or plant status as well as a selection of optimisation strategies for the performance scope.

Current Image of Intralogistics. Everything so Nice and New Here!

Sometimes art delivers the best guideline: “Everything is so colourful here”, as sung by the old punk singer Nina Hagen many years ago in her song “TV-Glotzer [TV gawkers] (White Punks on Dope)”, and of course was referring to the television. We would rather take a look at intralogistics! “Everything is so nice and new here”: Changing the phrase that has become a familiar quotation. Every word of it is true. Currently everything is changing in the industry. It is so nice, because the economy is soaring, contrary to all typical German prophecies of doom. It is also new, as we finally have technology and software available for improving in-house material flows that before we could have only dreamed of. Discuss it with Michael ten Hompel, the Director of Fraunhofer IML in Dortmund, it is worth it.

.jpeg)